Electroplating Workers

Overview

Introduction

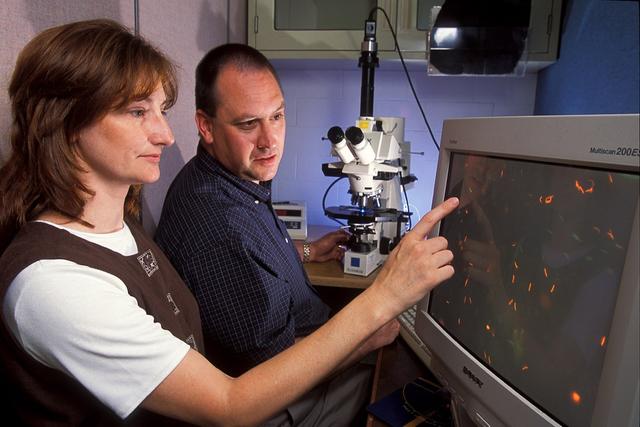

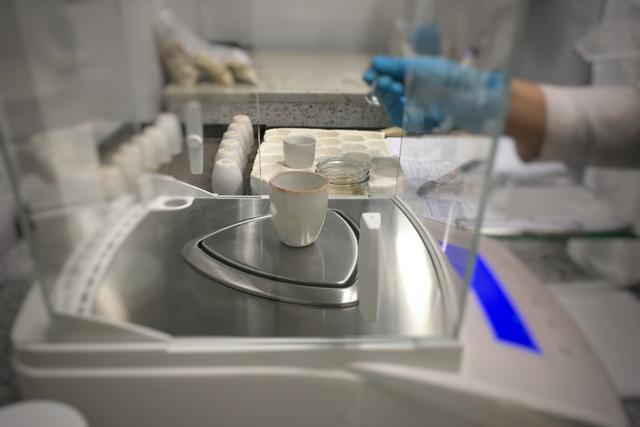

Electroplating is the process of plating, or coating, an article with a thin layer of metal by using a liquid solution of the metal and an electric current that causes the metal to deposit on the articles surface. Some objects that are electroplated are automobile bumpers, grills, and trim; metal furniture; aircraft parts; electronic components; small appliances; and plumbing fixtures. Electroplating provides a protective surface and helps an object resist wear, corrosion, or abrasion. The various workers who carry out this process are known...

Quick Facts

Median Salary

Employment Prospects

Minimum Education Level

Experience

Skills

Personality Traits

Earnings

The earnings of electroplaters vary widely depending on skills and experience, the type of work, geographical location, and other factors. The U.S. Department of Labor (DOL) reports that the median hourly wage of platers in May 2023 was $19.11, or $39,740 annually for full-time work. The top 10 percent earned $57,550 and the lowest 10 percent earned $30,730.

The DOL reports the following...

Work Environment

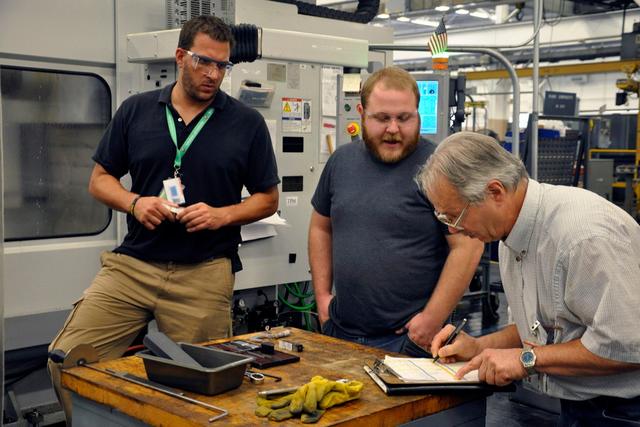

Job conditions are generally good for platers today. In most plants, improved ventilation systems have reduced the odor and humidity problems that used to be common. Many plants are completely modernized, with automated electroplating equipment. Although there are some hazards associated with using strong chemicals, good safety practices and protective clothing minimize the risk of injury. Elec...

Outlook

The number of jobs in the electroplating industry is expected to decline by 11 percent from 2023 to 2033, according to the U.S. Department of Labor. Although there is expected to be a greater number of electroplated items produced, a growing trend to automate the processes related to electroplating will reduce the number of workers needed. For this reason, employment levels in this field will n...