Forge Shop Workers

Overview

Introduction

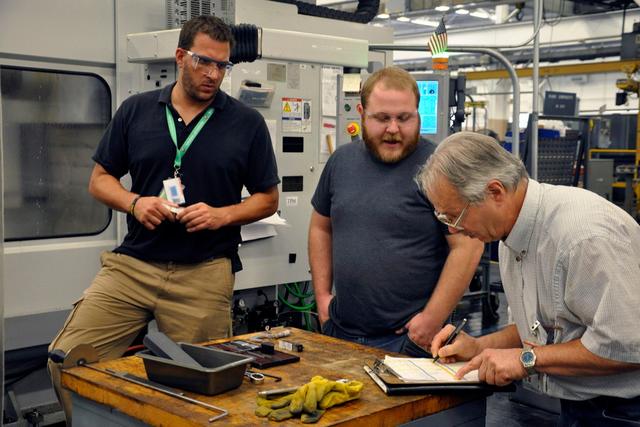

Forging is a process of shaping and conditioning metal by pressing, pounding, or squeezing it, with or without heat. In general, forge shop workers set up and operate equipment in which hot metal that is to be shaped into something useful is held in place on a die or metal form. A second die is then dropped or forced against the hot metal, pressing it into the desired shape. The Forging Industry Association reports that approximately 35,000 people are employed in the industry in the United States and Canada.

Quick Facts

Median Salary

Employment Prospects

Minimum Education Level

Experience

Skills

Personality Traits

Earnings

Forging machine setters, operators, and tenders-metal and plastic earned median annual salaries of $46,990 in May 2023, according to the U.S. Department of Labor. Salaries ranged from $31,860 to $64,070 or more. Fifty percent of these workers earned between $38,390 and $54,220. First-line supervisors of production and operating workers earned median annual salaries of $65,930.

Overtime w...

Work Environment

Historically, forge shops were noisy, hot, dirty, and presented more hazards than most manufacturing plants. However, many shops have installed equipment that has minimized the discomfort and dangers associated with forging. Heat deflectors and ventilating fans reduce heat and smoke. Improved machinery and shop practices help cut down the noise and vibration from hammers. Workers are given safe...

Outlook

The U.S. Department of Labor reports that employment for forging machine setters, operators, and tenders, metal and plastic is expected to decline by 16 percent from 2023 through 2033. Since the 1980s, employment in forge shops has declined. Because U.S. forge shops have had to become more cost-efficient in order to compete with foreign companies and nonforged materials, they have been automati...